Sunflower Pre-Treating

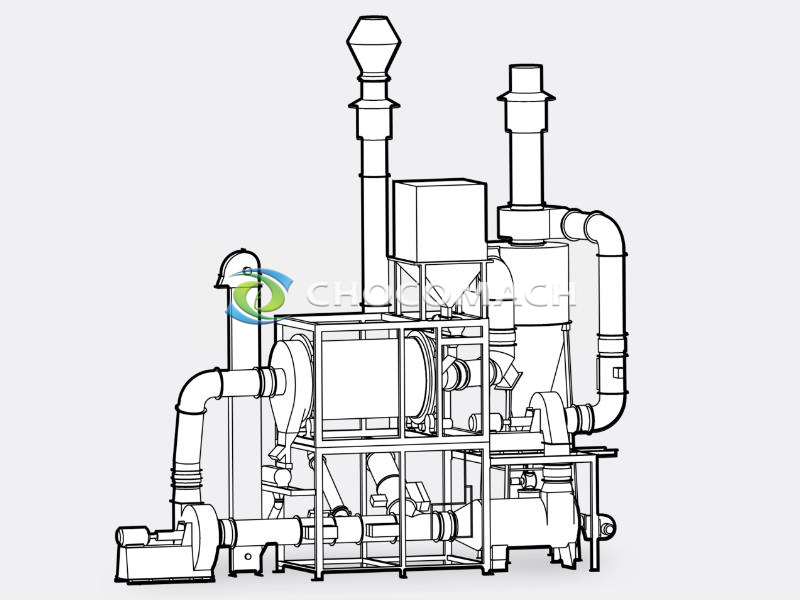

Batch Sterilizing Reactor for sterilizing cocoa beans and create shell popping effect

Feeding of hot beans from the roaster directly to the steam treatment in the reactor

Short and efficient steam pressurizing (1,5 – 2,5 bar) for minimum moisture intake and maximum reduction of bacteria below 500 cfu (*) per gram

Continuous discharge towards the breaking and winnowing process

DESCRIPTION

When using a nib alkalizer, the shell must be first removed with the winnower, which gently loosens the shell from the kernel. In order to develop the desired color and flavor profile the nibs are alkalized (Dutching method). Over the last 30 years, nib alkalization has been the most common method, since it is the most flexible system regarding flavor, color, and pH influence. In the latest alkalizing system it is possible to treat nibs with a very high moisture content. With the addition of up to 35% of a hydrous alkaline solution, pH values up to 8,0 can be achieved, together with respective changes in color and taste. In combination with the nib roasting this results in a very effective reduction of bacterial count to values of normally < 100 – 1000 germs/gram.

Good mixing ensures a homogeneous color and taste throughout the complete batch. The alkalizing vessel has a special (wider) design and is equipped with a tapered screw to insure the shortest mixing time with best in class mixing performances. In this special design it is even possible to start up the wet mix after a production stop.

BENEFITS

– High pressure and vessel temperatures possible

– Energy savings up to 25%

– Bacteria counts below 500 cfu(*) per gram after sterilization

– No risk of contamination of clean nibs

– Excellent release of the shell for optimum shell separation in downstream winnowing

– Short and low pressure steam treatment for moisture intake only on the shell

– Fast emptying and filling

(*) cfu = colony forming unit = rest count of bacteria after sterilising

| Types | Capacities [kg / hr] |

| Alkalizer type AL 3500 | 2.000 – 3.500 |

| Alkalizer type AL 5000 | 3.500 – 6.000 |

Service Tel:

+86 136 0865 6963

+86 199 3799 5959

0086 0379-61127277

Email:

chocooilpress@gmail.com info@chocomach.com

Wechat:

WhatsApp:

+86 199 3799 5959